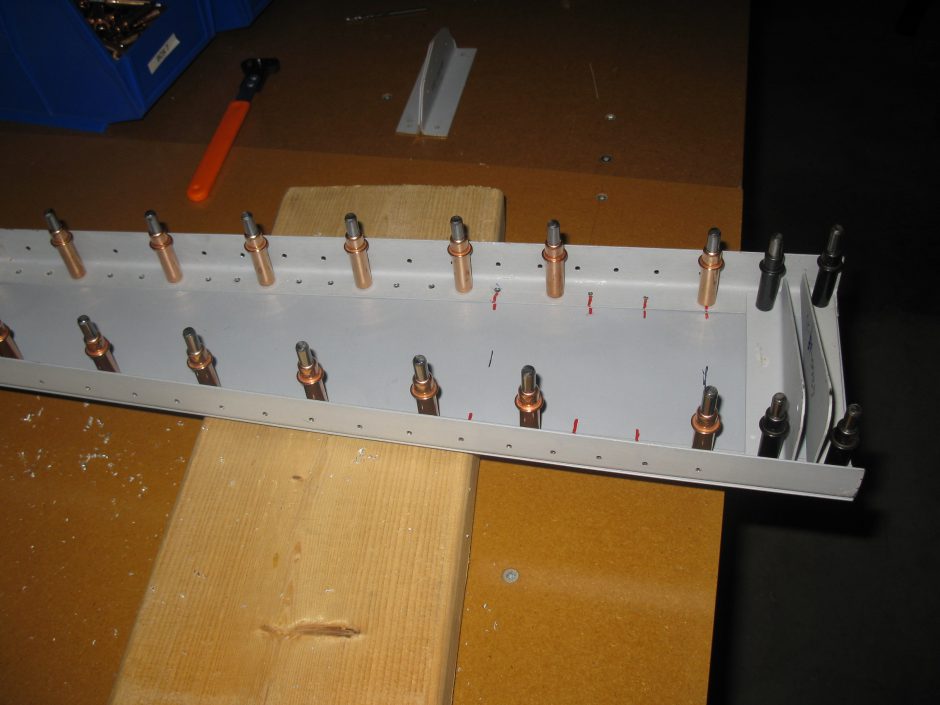

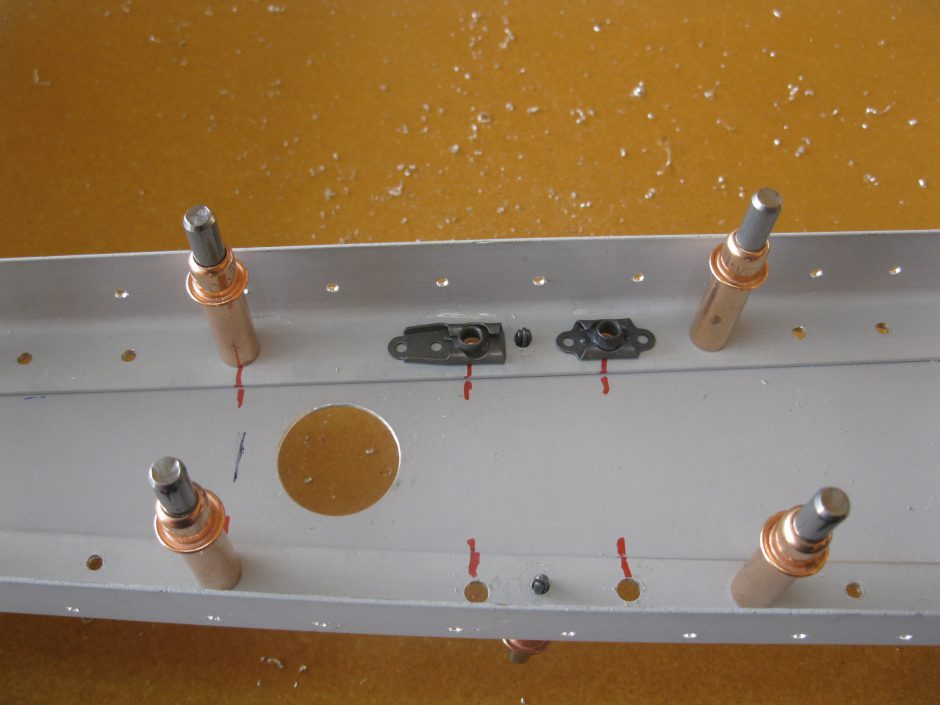

My work on the rudder spar is continuing today with mounting the hinge nutplate assemblies. In the picture below I have started to mark where the hinge brackets need to attach and I have identified these with a Red Sharpie marker. The hinges on the S-51 rudder are bolted on and as the internal faces of the rudder assembly are not accessible after it’s built, you will have no access to the nuts if you attach the hinges with bolts. Because of this, I’ll be installing nutplates on inner side of the rudder spar to facilitate removal of the hinges should I need to.

Identifying Rudder Hinge Locations

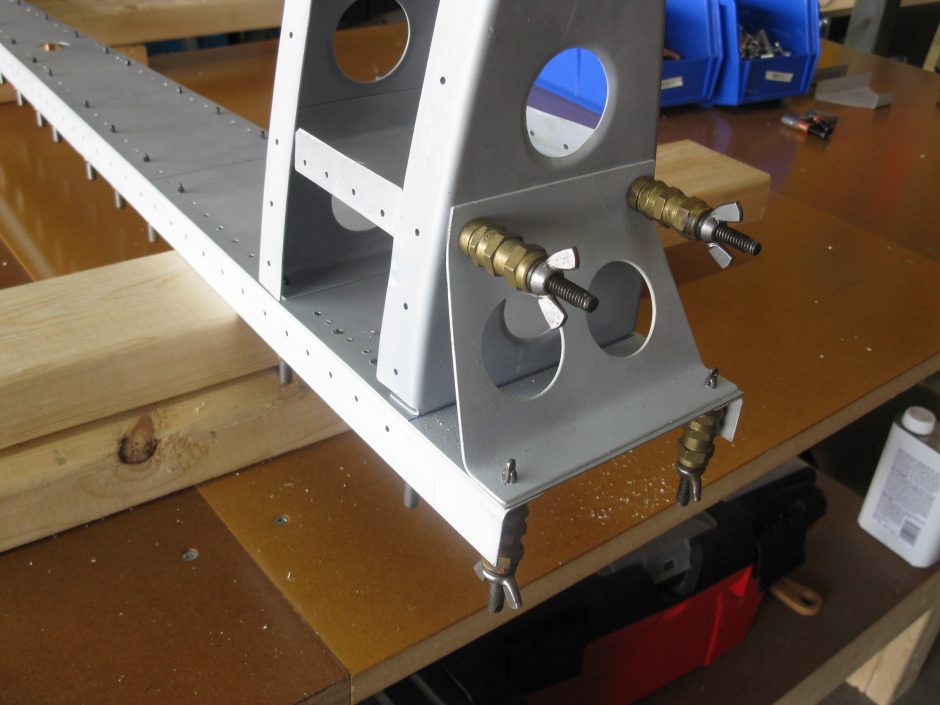

This is a picture of the lower end of the rudder spar. The bracket you see here is where the rudder push/pull control tube attaches. Unlike on RV and other homebuilt aircraft that have the rudder bellcrank visible externally, the S-51 has all parts of the rudder control system internal within the aircraft.

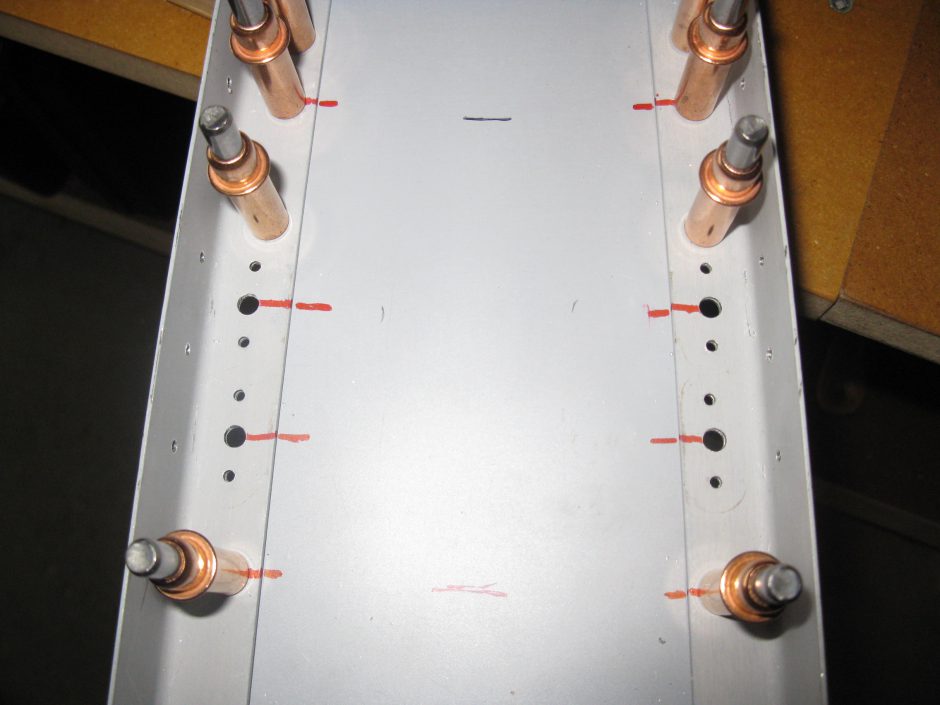

Drilling Perfect Nutplate Holes

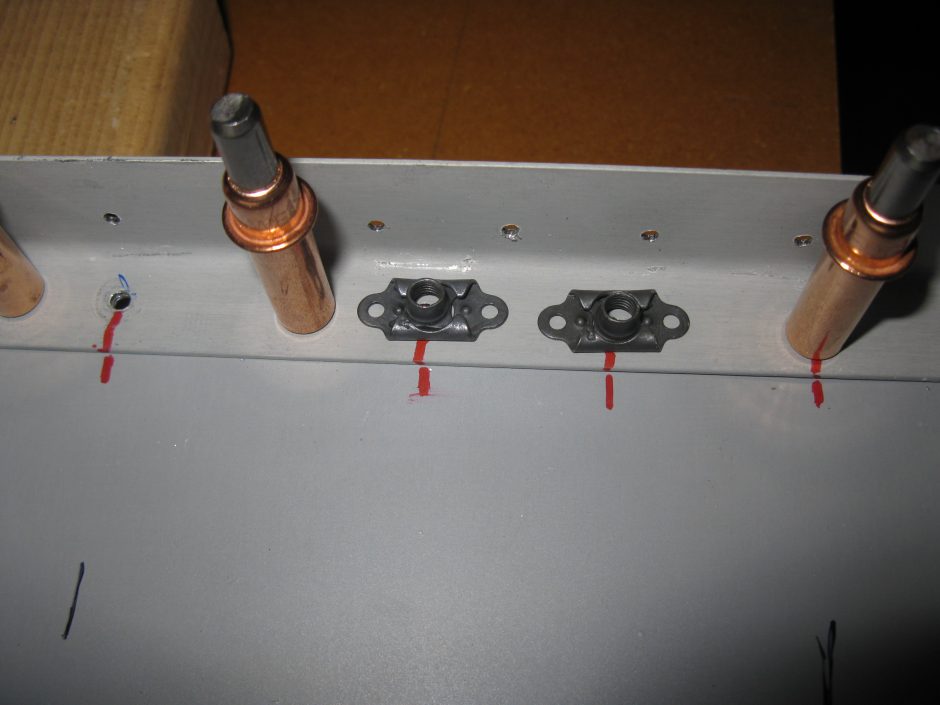

In the picture below I have placed two nutplates in the rough locations. The ears on the side of the nutplate are for the mounting rivets. When drilling the locating holes for mounting the nutplates, I use a nutplate jig to ensure that I get accurate holes.

In the picture below it is the tool with the orange handle. These little guys aren’t the cheapest tools around, but by using them, it sure speeds up the process of trying to drill perfect nutplate holes. As you can see on the tools, there is a large locating pin in the middle of the tool head. On the one side is a small hole with a bushing to allow for a #40 drill bit. On the other side of the head you will see a smaller locating pin (if you guess that it’s a #40 size – you’re correct!). After you drill the one side, you can flip the tool over and both locating pins will hold the correct position while you can accurate drill the last hole.

And here are the results after using the nutplate jig tool. I’m really happy with this.

Various Type of Nutplates

In the picture below you will notice that I was not able to use the standard styling of nutplate because I have a rivet hole interfering with the nutplate mounting clearance. Because of this, I opted to use a nutplate that has the rivet attach flange only on one side of the nutplate. This will allow me to still get the nutplate in place without getting too close to the existing rivet. There are tons of different nutplates to help you get into all kinds of tight spots.

How to reassemble?

Now I’m starting to move on to getting the rudder back together so that I can once again drill out the pilot holes and match drill the parts for final assembly. The picture below is showing the lower rudder structure coming together.

Please comment, I love to hear from my readers. Thanks again for coming along for this ride, you make my work worthwhile.

Leave a Reply