The Stewart S-51D Mustang

The Stewart S-51D is an all aluminum, two-place, dual control, aerobatic, high-performance aircraft. It was designed to replicate the North American P-51D as nearly as possible and practical.

Stewart 51 History

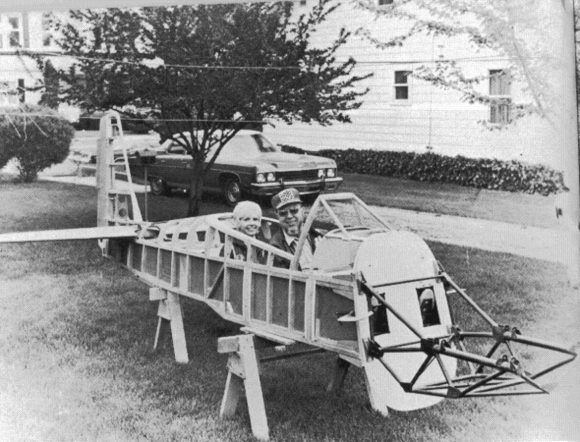

Jim Stewart developed the Stewart S-51D over a period of around 20 years. Way back in 1968, Jim began to design the S-51, a 70% scale version of the WWII P-51D fighter. The initial design was a wooden aircraft with a small block Chevy V-8 engine. Jim went back to the drawing board and started over with the plane being an all aluminum design. Eventually, several sets of plans were sold for this early version of the S-51, and two of these plans-built S-51’s were built and flown.

Jim continued to refine the S-51 design and increased the powerplant from the small block Chevy V-8 to a big block. Moving forward several years to the early 1990’s Jim was satisfied with the design and began to offer kits for the S-51.

During this time, the S-51 was the most accurate scaled P-51D replica available. The S-51 had significant performance increases over the smaller SAL and FEW kits available at the time. The complexity of the S-51 also surpassed the other kits.

The S-51 continues to remain the most accurate P-51D replica aircraft. By the late 1990’s the S-51 performance became surpassed by the Thunder Mustang, which is of carbon fiber construction. The Thunder Mustang is slightly larger in size and incorporates modifications directed at the air-racing market such as clipped wings.

The S51 was very popular during the period as it truly was a unique aircraft. The S-51 was also a regular feature of the Oshkosh airshow for several years with Elliot Cross at the controls demonstrating the aerobatic capabilities. The Stewart 51 company now had its product offering and great publicity which resulted in modest sales of the kit. On the flip side, the initial kit pricing turned out to be far below the actual cost of production and eventually the Stewart 51 company experienced financial difficulty and unfortunately became unreliable in fulfilling customers orders for kit and component deliveries (of which the customers had already paid).

In the early 2000’s the Stewart 51 company was sold to Precision Aero Engineering of Camarillo, CA, who assumed the rights to the aircraft design, parts inventory, and the S-51 prototype. At the time PAE amidst developing a V-8 powerplant for the S-51 as well as being available for other similar homebuilt aircraft.

As part of the agreement in the business transfer from Stewart 51 to PAE, the terms included that PAE would assume Stewart’s outstanding obligations suppliers and to the builders still awaiting parts deliveries. PAE did not fulfill these requirements and eventually experienced financial troubles of their own. PAE was evicted from their facility in Camarillo, and the majority of the company assets were put up for sale at auction.

In July 2007 a group of builders recovered all the rights to the S51, the prototype and all of the parts and tooling in the possession of PAE. Currently, Stewart 51 Partner, LLC is the holder of the S-51 design rights, production tooling and parts inventory.

Design Philosophy

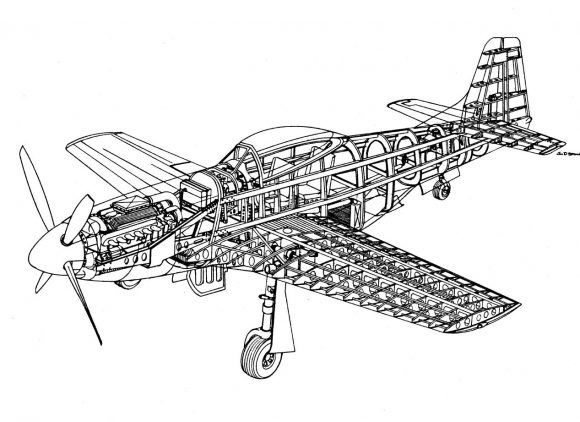

The S-51 isn’t your average homebuilt airplane, constructed from over 3400 individual pieces plus some 30,000 rivets. That’s roughly equivalent to a Cessna 310, in parts and fasteners. To take this aircraft to a more advanced level, the hydraulic retractable landing gear and big automotive V-8 engine with a reduction drive to the constant-speed propeller certainly add to the overall complexity.

The design of the S-51 was to keep as close as possible to the North American P-51D as nearly as possible and practical. The airfoil, for instance, is the same NASA 66-215/-216 as the P-51. Various minor modifications have been designed into the S-51’s flight surfaces, to ensure safe flight characteristics with the average pilot in mind, without deterring from the spectacular performance.

The S-51 was designed to be as small as possible, to keep the frontal area (read that drag) small and the power required low. It was also intended to be a full size two place aircraft. That is how Jim Stewart arrived at a scale factor of 70%.

The S-51 kit was to be delivered as a prefabricated and preassembled. All of the welding, metal forming, and in jig assembling was to be completed by the factory. In keeping the kit as “buildable” as possible it also meets the FAA 51% rule.

It has taken years for Jim Stewart to design and develop the S-51, and it has it all; The performance, the appearance, the charisma of the great P-51 Mustang. If one were to truly want a Mustang but can’t quite manage the “big” one, the S-51 is the solution.

The Airplane

The S-51 has retractable landing gear, flaps, and a constant-speed propeller and with all this complexity, come many systems. The landing gear utilizes an electrically driven hydraulic pump. All three wheels retract, and the main gear doors operate the same as a P-51. The tail wheel is locked and unlocked with the control stick, just like the P-51, and is steerable when locked. The wheels are 6.50 x 800 which are to scale and permit operation from grass runways.

The ailerons and elevators are push-pull tube operated. The rudder is cable operated. The elevator and rudder have electric trim. The flaps are electric and controllable through 45°.

The Cockpit

The cockpit accommodates two full-size people and is laid out with the rear occupants’ rudder pedals located beside the front seat. The front seat will accept pilots over 6-feet, and more than 200 lbs., and the back seat will manage passengers up to 6-feet and 180 lbs (but it will be tight).

Both seating positions have control sticks, with only the front seat having a throttle quadrant. The S-51 throttle is set up like a P-51, with the mixture lever under the quadrant. Below the throttle on the left side panel is the land gear selection lever and flap lever console. The instrument panel will accommodate and IFR panel with radio stack and additional rack space in the center console below.

The center panel of the windscreen is 1/2-inch thick, and the side panels are 1/4-inch. The bubble canopy is blown from 1/4-inch thick cast acrylic. To the right of the instrument panel is the canopy crank, which positions and locks the canopy. Visibility is unequaled. The canopy is jettisonable. Although the S-51 has a long nose, it is narrow, leaving forward visibility relatively unencumbered.

A small luggage rack can be installed aft of the rear seat.

The wings are designed with “hard points” which provide jack points as well as mounting provisions for pylons, should external tanks or baggage pods be desired; Each limited to 250 lbs.

The Powerplant

The S-51 kits did not include the engine. Before we get too deep into the big block Chevy V-8 conversion used in the S-51, let’s review the P-51 Mustang powerplant.

The Rolls-Royce Merlin engine powered the P-51 Mustang. The Merlin is a 60-degree, V-12, liquid-cooled piston engine, and it is very narrow. It was, therefore, necessary for Jim Stewart to design the S-51 around a narrow, liquid-cooled engine. The only problem was that when Jim began to design the S-51, none existed.

Back in 1970, a 200+ h.p. small-block V-8 engine was built up using a HY-VO chain gearbox. This engine was tested for the next several years and finally flown in the two early plans built S-51 aircraft. These engines worked well and gave no problems. When it came time to design the S-51 kit version, Jim decided to move up to the 400 h.p. and higher range of big block engines.

The big block engine power increase reduced the expected fatigue life of the chain to an unacceptably low number, and therefore Jim designed an all new propeller reduction gearbox. The Propeller Speed Reduction Unit (PSRU) utilizes a significant spur-gear, six pitch gears and a reduction ratio of .469 (2.13:1). The PSRU can handle well over 800 h.p. The propeller shaft is sized to fit the flange of Hartzell 4-blade steel propellers. Engine oil lubricates the bearings which are ball and roller; The oil is directed to the prop governor, then through the prop shaft for pitch control.

The engine used in the prototype S-51 started life as Chevy 454 cubic inch, cast iron block, high-output, liquid cooled V-8. To make the engine compatible with the PSRU and to have proper propeller rotation, the timing chain was replaced with gears, reversing the crankshaft rotation. Other items added were a flywheel, torsional damper, dual plug aluminum heads, electronic ignition plus distributor ignition, dry sump oil pump, prop governor, and an Airflow Performance mechanical fuel injection system. The engine weight was 740 lbs and produced 400 h.p. at 4700 rpm.

The next concern was cooling. A custom built aluminum radiator was used. The glycol/water mixture cools approximately 40° F as it passes through the radiator. The radiator duct outlet door is electrically operated and when closed still has a small outlet opening. In cruise, the outlet duct door can be closed, without increasing the coolant temperature and several mph is gained.

A coolant header tank is mounted high and forward of the engine. A fifteen-pound pressure cap is used and excess coolant, from expansion, is piped to a 2-gallon recovery tank on the firewall. A liquid cooled oil cooler is placed in the engines water outlet line and adds 10° F to the coolant on its way back to the radiator. The coolant returns to the engine at 150°F.

The fuel injection system is a mechanical port injection type. This system utilizes an engine driven pump and two emergency electric pumps. Air is introduced through the engine cowl chin scoop, then ducted under the engine, through an air cleaner and up behind the engine to the throttle body. The mixture control is manual.

Current builders are using Chevy big block engines in the range of 520 cubic inches and larger. Several of these also have been supercharged approaching 800+ h.p.

Turbine S-51

For various reasons, several S-51 builders have chosen to go away from the auto-engine conversion powerplant to using a Walter 601D turbine. The 601 develops about 725 hp and weighs about 400 lbs. Because the turboprop engine is much lighter than the Chevy, the nose of the aircraft needs to be lengthened about 11.5 inches. The original cowling can be used by adding 8.5 inches to the aft side and 3 inches at the front.

The prop used is an AVIA 508 and has a 99-inch diameter. On takeoff, the aircraft climbs at 4000 fpm at about 113 knots. Because this is a turbine engine, it is much more efficient at higher altitudes. For instance, one builder reports that when taking short trips and staying low, he sets the engine at about 50 percent power, which is 1800 rpm which yields about 186 knots at 37 gph fuel flow. When taking longer trips, cruising upwards of 10,000 feet, the power setting is 65 percent which gives 239 knots at 40 gph.

Other modifications include increasing the fuel capacity of the S-51 to 150 gallons. The entire leading edge of the wing and inboard wing root sections between the spar are fuel tanks.

Propeller

The propeller used on the S-51 is a 4-blade Hartzell constant speed prop with a 91″ diameter. Take-off propeller rpm is 2200 and cruise settings are 1500-1800 rpm. The prop governor is cog belt driven at the firewall end of the engine and is connected to the oil scavenge/pressure pump.

Construction Details

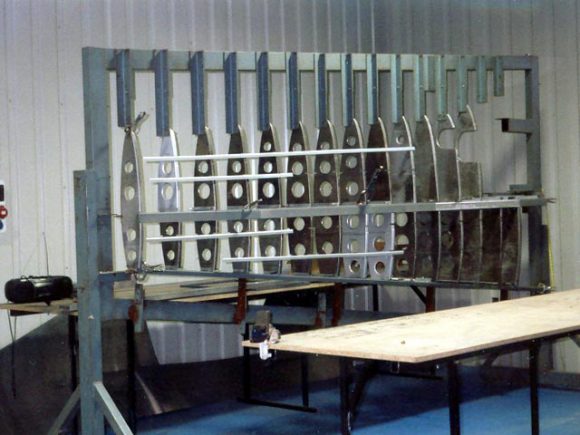

Knowing that the S-51 is a complicated aircraft to build, Jim Stewart devised a system to make it very builder friendly. The entire airframe was assembled in the company jigs. The factory would install temporary “pop” rivets in every 5th or 6th hole for shipment. When the builder received the kit, it looked like an airplane!

All formed parts were formed and in place; all welded parts were supplied, and nearly all of the rivet holes were pilot drilled. Many of the non-systems parts were in place. This way the builder started with airframe assemblies rather than a box full of parts. With more than 3400 parts and 30,000+ rivets, this is significant!

When the airframe assemblies were placed in a simple ‘holding fixture’ it was relatively straight forward to finish drill, countersink, prime and rivet the structures.

Skin thickness varies from 0.040″ to 0.063″, permitting countersinking. The control surfaces are 0.025″ and require dimpling. The rudder is fabric covered, just like the P-51.

It was estimated that a reasonably capable builder would require approximately 3000 – 4000 hours to complete the S-51 build. In reality, builders have spent considerably more time than the estimate. One builder has even quoted that he could have built four RV’s in the time it took him to build the S-51.

Flight Characteristics

The S-51 is a fast, maneuverable, fun fighter-like airplane. The control forces are heavier than many amateur-built aircraft and meet military specifications for training and fighter aircraft.

The aircraft has relatively strong static stability, and stalls occur at about 63 knots. Stalls are docile, preceded by about five mph, with tail buffet followed by a slight wing drop and average pitch down. Full throttle recoveries induce a good bit of yaw but are virtually without the potentially serious torque roll. Full aileron roll rate is about 45 degrees per second which are very similar to the P-51.

On take-off, the S-51 accelerates at a very high rate and lifts off in a relatively short distance, but the wide gear stance and rudder trim make the engine torque very manageable. The staccato from the 500+ h.p. engine is most impressive!

Landing characteristics are similar to other high-performance aircraft. The rate of descent is controlled by the throttle, and it is not closed until the wheels are rolling. The narrow cowl affords good visibility during the approach.

The landing approach speed is about 90 knots and is flown at a relatively high rpm to reduce the sink rate common to this type of aircraft.

With a gross weight of 3500 lbs and with 500 h.p. the S-51 has a power loading nearly identical to the P-51. On the other hand, the wing loading is about half, contributing to the relatively docile handling.

The aircraft is capable of flying all basic maneuvers. Pilot reports are very positive, noting that the aircraft “begs you to roll it.” Nose down acceleration requires close pilot attention.

In general, the S-51 has the feel and ride of a “heavy” aircraft like a P-51.