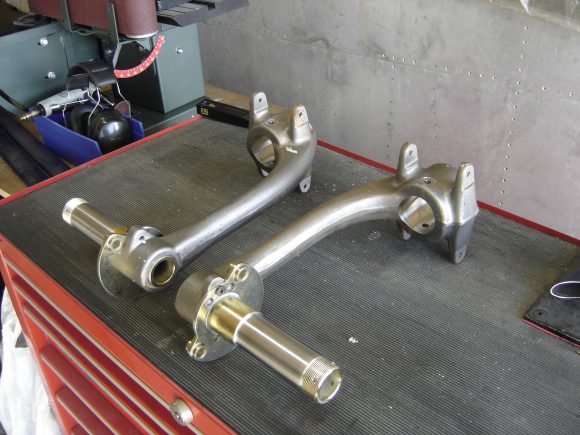

I have just returned from Oshkosh Air Venture and picked up my main landing gear forks. While at Oshkosh I was able to meet up with a fellow Stewart 51 builder who brought the forks with him to the show. This builder did a bunch of machining on the new forged steel forks which was a huge help for me.

The Cost

The total cost of these as shown in the photo are: $2241.43 USD ($2355.06 CDN)

Forks: $1700 USD ($1802.41 CDN)

Axles: $204.60 USD (S215.82 CDN)

Brake Mounting Plates: $91.83 USD

Machining: $245.00 USD and CDN (Exchange = Par!!)

A Brief History of the Forged Forks

Originally the Stewart 51 kits were supplied with cast aluminum main landing gear forks. Over time as a few of the first builders got their planes flying some cracks were found developing in the area where the axle comes through the fork. Some reinforcing plates were made and bolted on to help distribute the stresses, but problems persisted. There was one or two instances where on rollout after landing that the forks fractured and resulted in a runway excursion.

Starting sometime in 2008, one of the S-51 builders was able to acquire a pair of landing gear forks from a Thunder Mustang to replace the cast aluminum forks that came with his kit. The Thunder forks are forged from 4140 steel and are heat treated to RC38, then magnaflux inspected. The axle to strut vertical dimension was identical to the aluminum fork and the scissors would fit with no modification.

The Thunder strut diameter is slightly larger as is the axle bore. This required machining a sleeve in each to adapt the existing Stewart strut and axle. The weight difference between the two struts is only a little over a pound. Aside from the advantage of strength over the aluminum forks, the Thunder Mustang forks are a dead ringer in appearance to the original P-51 Mustang forks.

Eventually contact was made with the Thunder Mustang builders group about the possibility of making a run of these forgings as there was great interest among the S-51 Builders Group. Approval was granted to use the forging dies and the order was placed for 25 sets. Once the forks were delivered, one of the guys in the S-51 Builders Group did all the final machining and supplied the forks to the builders with machining to 0.005″ undersize.

Update: In early 2016 another run of forged main gear forks was produced. You can read more about it here, as well as some good pictures of the forgings.

Main Landing Gear Forks

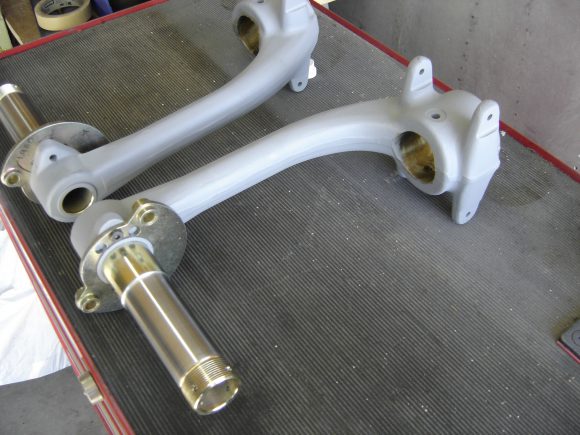

As these main landing gear forks aren’t going to be used any time in the foreseeable future, I want to be sure to protect them from surface corrosion and rust while they are in storage.

As always I love to hear from my readers. Thanks again for coming along for this ride, you make my work worthwhile.

Leave a Reply